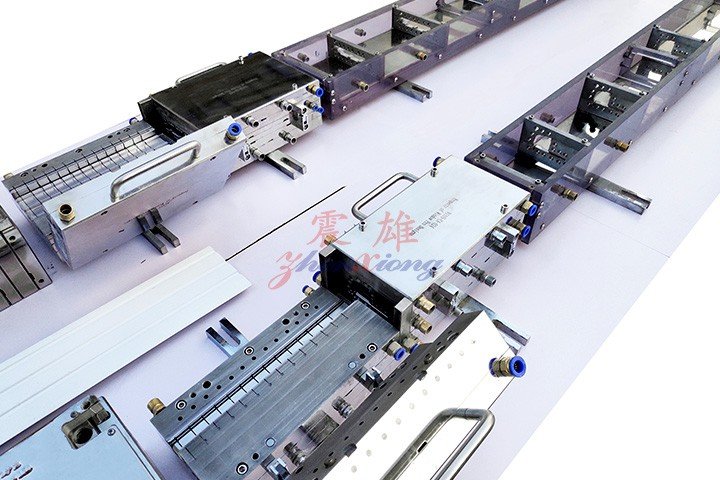

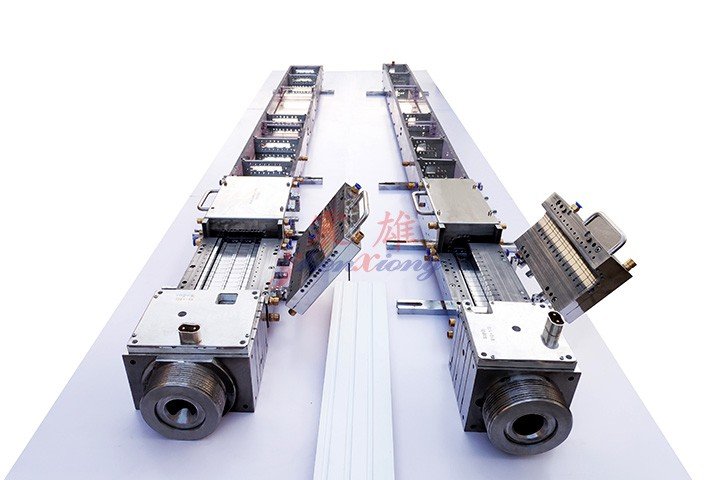

Our company has a series of modern and high-precision processing equipment, including wire cutting, machining centers, CNC machine tools, 3D simulation systems, etc., which can process and produce various types of profile moulds.

Core advantages:

●Automatic CNC machine tools have high machining accuracy and small errors in profile moulds.

●Customized profile mould support: design and production based on customer specific requirements.

●The profile mould is made of 40Cr mould steel material, quenched, tempered and forged, with high strength, wear resistance, and high mould accuracy.

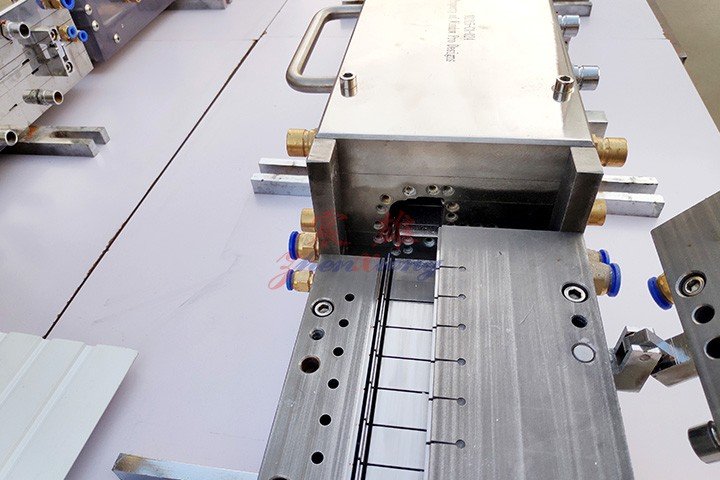

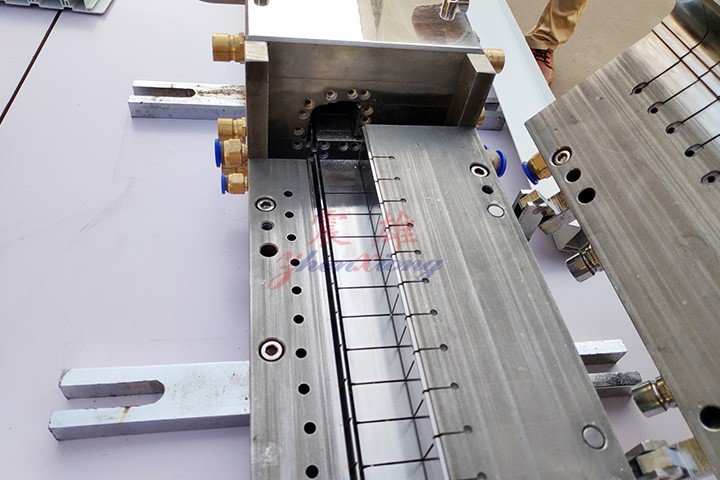

●Co-extrusion mould:Co-extruded colored surface, with uniform and consistent co-extruded layers for easy post-processing.

●The profile mould is suitable for the production of various formulas and different equipment.

●The core rod of the profile mould is specially treated, which has strong wear and corrosion resistance, and a long service life.

●The cooling system design of the profile mould is advanced, with good cooling effect and easy cleaning.

●Can be reset with high precision, ensuring the continuous production capacity of profile moulds.

●The profile moulds are tested first and can only be shipped after passing the inspection.